70W Backpack Laser Cleaning Machine Laser Rust Removal for Metal Rust Painting Coating Grease Dirty

70w backpack laser cleaning machine laser rust removal system (LBQX-300) Laser cleaning equipment is high-tech product f

Description

Basic Info

| Model NO. | LBQX-300 |

| Laser Wavelength | Fiber Laser |

| Laser Classification | Solid Laser |

| Type | Optical Fiber Laser Marking Machine |

| Marking Method | Scanning Marking |

| Consumable Items | No |

| Working Life | 100,000hours |

| Protection Cover | Can Be Customized |

| Laser Power | 70W |

| Transport Package | Wrapping Film & Export Standard Wooden Cases |

| Specification | 835*500*925mm |

| Trademark | Label Laser |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 300/Units |

Product Description

70w backpack laser cleaning machine laser rust removal system (LBQX-300)

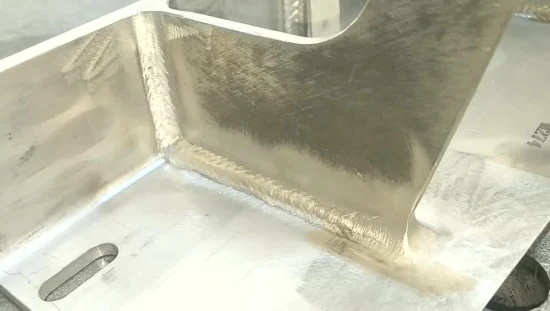

Laser cleaning equipment is high-tech product for a new generation of surface cleaning.Clean resin, oil, stains, dirt, rust, coating, plating, paint on metal surface by removing the surface coating without chemical reagent, medium, dust, water. .Workable on both flat and curved surfaces.LBQX-300 is a new generation backpack laser cleaning machine of Label combines light weight, easy operation, high-efficiency, non-contact and non-pollution. Used for cleaning the rust of cast iron and carbon steel plates, cleaning the oil pollution of stainless steel and mold gears, aluminum plate, cleaning the oxide of stainless steel, has a clean surface and does not damage the base metal.Product advantages:1. Portable design. Integrated design, all in one whole system, compact structure, backpack structure, easy to carry.

2. High flexibility. Flexible optical fiber structure, flexible operation.

3. Lightweight structure design. The overall volume is small, about 0.015 m2, and the weight is light, about 10kg.

4. Software diversification. It has circular scanning, cross scanning and S-shaped scanning functions,

and can customize parameters, meet different materials and scenes.

5. Intelligent memory. There are 8 kinds of parameter templates synchronously, which is convenient for reuse.

6.High efficiency and environmental protection. High cleaning efficiency, time saving, high precision, no damage to the substrate, and strong environmental protection.

7.Wide application scenarios. It can meet the application requirements of scenarios that cannot be reached by large cleaning

equipment, and it is flexible application, fine cleaning.

Product Features:

- Non-contact cleaning,no damage for parts.

- Precisely work on the selected location and size

- No need any chemical cleaning agent,no consumables,safety and environmental friendly

- Simple operation: Power on,automatic cleaning can be realized by hand or cooperating with manipulator.

- High cleaning efficiency

- Cleaning system is stable and requires almost no maintenance

- Shipbuilding industry

- Auto parts

- Rubber mold

- High-end machine tools

- Tyre mould

- Railway

- Environmental protection industry

- Others

Product Parameter:Optical parameters:

| Model No. | LBQX-300 |

| Laser power | Pulse 70W |

| Laser wave length | 1064nm |

| Beam quality M2 | ≤ 1.6 |

| Power regulation range (%) | 10~100 |

| Single pulse energy (mJ) | 1.5 |

| Optical pulse width (ns) | 100-120 |

| Pulse frequency | 50-170KHz |

| Type of cooling | Air-Cooled |

| Output power stability (%) | < 5 |

| Laser output beam diameter (mm) | 6-8 (1/e ²) |

| Output beam ellipticity (%) | ≥90 |

| Laser on time (us) | 110-140 |

| Laser off time (us) | 110-150 |

Output optical cable parameters

| Optical fiber cable length (m) | 1.5m (customizable) | |

| Electrical Parameters | ||

| Power supply voltage (AC) |

| |

| Maximum current loss (A) | 5 (± 1) | |

| Rated power consumption (W) | 400 | |

| Other parameters | ||

| Operating ambient temperature (ºC) | 0~40 | |

| Relative humidity of working environment (%) | 10-96 | |

| Storage temperature (ºC) | 10-60 | |

| Cooling mode | Air cooling | |

| Preheating time (min) | 10s | |

| Overall dimension (mm) | 440mm * 320mm * 190mm | |

| Operating weight (kg) | about 10kg | |

Parameters of laser cleaning head

| Field mirror configuration | F160, F254 |

| Scanning line length (mm) | 0~100mm(F160) 0~160mm (F254) linear adjustable |

| Scanning line width (mm) | 0~20mm (linearly adjustable) |

| Maximum galvanometer speed (mm/s) | ≥ 15m/s |

| Weight of cleaning head (g) | 1kg (excluding optical fiber output head) |

| Cleaning head size (mm) | 299mm * 82mm * 92mm |

| Cleaning head material | aluminum alloy |

Advantage Comparison

| Item | Laser Cleaning | Chemical Cleaning | Mechanical Polish | Dry Ice (CO2) Cleaning | Ultrasonic cleaning |

| Cleaning Method | Laser and non-contact type | Chemical agent,Contact Cleaning | Mechanical/ abrasive paper, contact cleaning | Dry Ice (CO2), non-contact type | Cleaning agent,Contact type |

| Hurt for workpiece | No damage | With damage | With damage | No damage | No damage |

| Cleaning Efficiency | High | Low | Low | Medium | Medium |

| Consumable | Just with Electricity | Chemical cleaning agent | abrasive paper grinding wheel, oilstone | Dry Ice (CO2) | Special Cleaning Agent |

| Effective | Excellent with high cleanliness | Common, Non-uniform | Common, Non-uniform | Excellent , non-uniform | Excellent , small cleaning area |

| Accuracy | Precise Control, High Accuracy | Non-control,Lowe Accuracy | Non-control,Common Accuracy | Non-control,Lowe Accuracy | Can not clear in special place |

| Safety / Pollution | No Pollution | Environment Pollution | Environment Pollution | No Pollution | No Pollution |

| Handling by workers | Simple Operation,Handheld / Automation | Complex process,It is with high requirement for operator, must have preventive measure | With much labor cost and must have preventive measure | Simple Operation, Handheld / Automation | Simple Operation, but have to add consumables |

| Cost Comparison | High first Investment , No consumables , Low Maintenance Cost | Low first investment, Extremely High Consumables cost | High first Investment, high consumables cost & high labor cost | Medium first Investment, high consumables cost | Low first investment, Medium Consumables cost |

About us Lable Laser :

Wuhan Label Laser Company Specializes in the R & D, production and sales of laser marking machine, pneumatic marking machine, electromagnetic marking machine and laser welding machine, laser cleaning machine since 2006."Laser + automation" and "Laser + intelligence"Our company launched the 2nd generation of leading products "Smart Marking Machine Workstation" to meet market demand.The intelligent workstation combines mechanical manufacturing unit, electrical control unit, motion control unit, CCD vision and detection unit, Internet card station unit, MES communication unit, ERP management unit, DPM code reading unit, weighing, measuring, detection unit, laser The ranging unit, FIRD identification unit, label printing and labeling unit, and other new technologies and processes to realize production line automation and system integration.With 16 years development, Label Laser has accumulated rich technical and design experience for industrial marking system, a large number of successful cases and well-known customers in industries of machinery, automotive, iron and steel, petroleum, petrochemical, aviation, electronic products, tools, instrument, apparatus, etc.

Why choose us Label Laser ??

- 16 years of researching and manufacturing experience

- Advanced technology, researching and development group

- More than 4000+ successful cases of marking solution accumulated in domestic and oversea markets

- 100% QC

- Utility Model Patent Certificates,involved 3M Flexible label paper marking,Nameplate Auto marking ,Engine cylinder block and head pass-type auto marking,Automobile forged wheel hubs pass-type auto marking, copyright of computer software,etc.

- ISO,CE,SGS certified

- Main transportation method: by sea.

- Other Option: by air or railway transportation.

A: Laser cleaning is typically a delicate process of creating a depth by removing the surface material, and acheieve the aim of rust removal. The laser cleaning systems at Label Laser are designed for non-contact processes. They offer better and more reliable solutions in terms of stability and deformity

Q: How to operate the machine? Is training necessary?

A: Laser cleaning machine is Automatic running, easy to install, control and operate. Operation manual with pictures will be provided . Generally speaking, an operator, who is not familiar with laser cleaning machine can still operate it very well

Q: In case machine exists the problem, how to do after sales service?

A: One-year warranty of the whole machine. Free to maintain if any problems during this period. Also we will assist you to solve problems in the future

Q: Is it possible to add customized protection cover?

A: Yes, customized protection cover is acceptable

Q: Any consumables for fiber laser cleaning machine?

A: No consumables. It's very economical and cost-effectient.Contact Us:Any questions,please feel free to contact us online or leave message right now!We will get back to you ASAP within 24 hours.

Prev: Perforated Panel Aluminum Composite Carved Wall Cladding Laser Cutting

Next: Laser Cut Decorative Facade Curtain Wall Panels Exterior Cladding

Our Contact

Send now