Hot Sale Laser Beam Hardening Machine Heat Treatment Surface Hardening Systems

Description

Basic Info

| Model NO. | LH-A019 |

| After-sales Service | Provide |

| Warranty | One Year |

| Application | Electronic Industry |

| Technical Class | Continuous Wave Laser |

| Control | Automatic |

| Power Density | Deep Fusion Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Silicon Steel Sheet Laser Welding Machine |

| Transport Package | Plywood Case |

| Trademark | sunrise |

| Origin | Cn |

Product Description

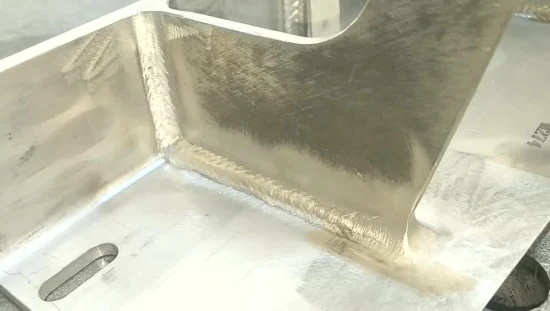

Product display

Laser quenching (also known as laser heat treatment) refers to the use of high-energy laser beam as a heat source, through the laser generated by the laser generator and external light transmission and focus, the formation of a high energy beam, the workpiece surface quickly heated to the phase transition region and quickly cooled, so as to achieve the heat treatment process on the surface of metal substrate. Compared with the traditional heat treatment method, it has the advantages of good controllability, strong directivity, high energy density, good uniformity of hardness of heat treatment layer and high degree of automation.

2.No need quenching water Due to fast heating speed of the laser, the hardening can be done immediately and no need cooling medium required. 3.No deformation no oxidation and decarburization Thanks to very precise laser beam, it will be only effect on hardening area, so there is no deformation. small heat affected zone, no deformation, almost no oxidation and decarburization.

4. Better hardening performance After quenching, the hardness is uniform and the structure is fine, which is higher than the conventional quenching (2-5HRC), the hardening layer is 0.2-1.5mm deep, and the wear resistance and life can be increased by 3-5 times.

5. No black hardening part There is no black part in quenching, and the shear performance is greatly improved.

6. Saving power consumption Power consumption of 7KW/h, comparing with conventional induction heating, it is very less.

7. No need skilled worker This is an automatic CNC machine with rotary table, so operator just need to put the workpiece.

8.Better working environment The machine is equipped with good-looking enclosure and the quenching water is not required, so it can be located clean workshop.Product Paramenters

| ITEM | Spec. | Description | Qty. |

| Laser | 2000W | Laser power: 10~1500W continuously adjustable. | 1 set |

| Fiber system | 600μm | Core diameter 600 m, length 15m | 1 set |

| Laser collimating head | TS-Q100 | Collimating focal length: 100mm, focusing focal length: 300mm | 1 set |

| Laser focusing module | TS-301P300 | Ensure speckle effect and heat treatment consistency | 1 set |

| Chiller | CWFL-2000 | Double temperature control to provide cooling water for laser and external optical path | 1 set |

| Multi-station four-axis system | TS-Q_SYS-4-900 | Professional laser CNC system, equipped with industrial control computer, to achieve XYZ moving, stroke X: 500mm, Y: 400mm, Z: 300mm (the specific stroke is determined according to the workpiece); Positioning accuracy: ≤±0.035mm Repeat positioning accuracy: ≤±0.01mm. Axis A and XYZ form A four-axis linkage | 1 set |

| Smoke purification system | Standard | Implement smoking and dust removal in work area (prevent pollution) | 1 set |

| Refrigerated dryer | 10HP,1.5M3 | Filter and dry compressed air | 1 set |

| Fixture | Customized | 1 set |

Prev: Professional Factory Made Cladding Equipment Machine CNC Laser Hardening Machine

Next: Laser Beam Hardening Systems Surface Hardening Machine

Our Contact